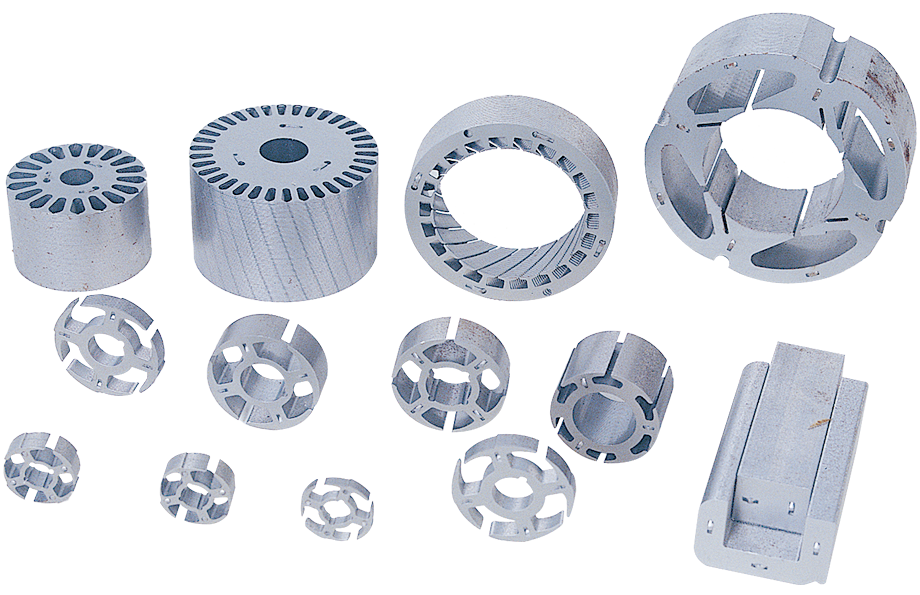

Service is provided by Shipwright Industrial Company Limited for more than 30 years. Depending on customers' requirement of the mold specification, the design of stamping dies progresses from loose lamination to interlocking and auto-skewing, from single row, double rows to mulitple rows. The chosen material of die plates and punches from normal high-speed steel to Tungsten Carbide. The design and assembly of lower die is from the single cutting plates, whole slot insert and slot segements combination. The Rotor skewing method is progressed from skewing gear to motor skewing control belt. The stator 90 degree or 180 degree rotation design helps the lamination overcome the material balance issue.

The overall specifications stated above are available in Shipwright Industrial Molding Division, which serves the customers for more than 30 years, manufactures more than 1200 moulds, and become first one who made the interlocking and autoskewing skill in Taiwan. Strong coordination with our excellent processing supplier, we are able to deliver high quality stamping moulds which provide longer stamping life and precisely dimensions for customers. Lamination division provides a better feedback for our stamping moulds, and we always look for new technology to improve our quality and reduce the customers' cost in respect of easy to use, easy to maintain, longer life, precision and etc., to ensure custoemrs' competitiveness in their market.

Our mould service scope is overseas in Australia, Egypt, Hong Kong, India, Indonesia, Iran, Japan, Mainland China, Malaysia, Pakistan, Philippines, Singapore, Thailand, Vietnam, and Etc.We also produce the interlocking and auto skewing control box to better fit our customers, since we have more than 20 years lamination background, and we know what the major concerns for the lamination factories are.

If you have more inquires about our molding service, please CONTACT US .